In the microscopic world, enabling complex 3D motions in micron-scale machines has long been a scientific challenge. Traditional micromachines are confined to 2D planar motion, limiting their ability to perform multitasking operations in complex microenvironments.

Recently, Prof. Shuailong Zhang’s team at BIT’s School of Integrated Circuit and Electronics, collaborating with multiple universities, reported a breakthrough achievement in Advanced Materials (IF=27.4). The study achieves 3D cross-plane motion transfer in light-driven multi-component micromachine systems for the first time, unlocking new potential in microfluidics, targeted drug delivery, and beyond. This work was selected as the journal cover, with BIT as the primary affiliation. Prof. Shuailong Zhang and Prof. Jiafang Li (BIT School of Physics) served as corresponding authors. Dr. Gong Li (Ph.D. candidate) is the first author. Guidance was provided by Prof. Guozhen Shen, Prof. Yeliang Wang, Prof. Huikai Xie (BIT), and Prof. Aaron R. Wheeler (University of Toronto).

I. Research Highlights

I. Research Highlights

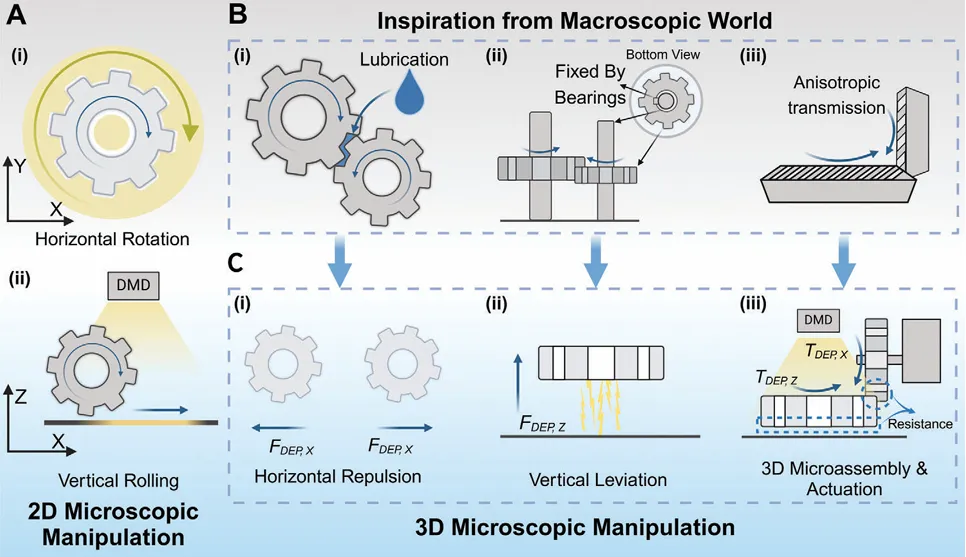

Multi-component micromachine system operating in 3D space.

Optoelectronic Tweezers (OET) Innovation

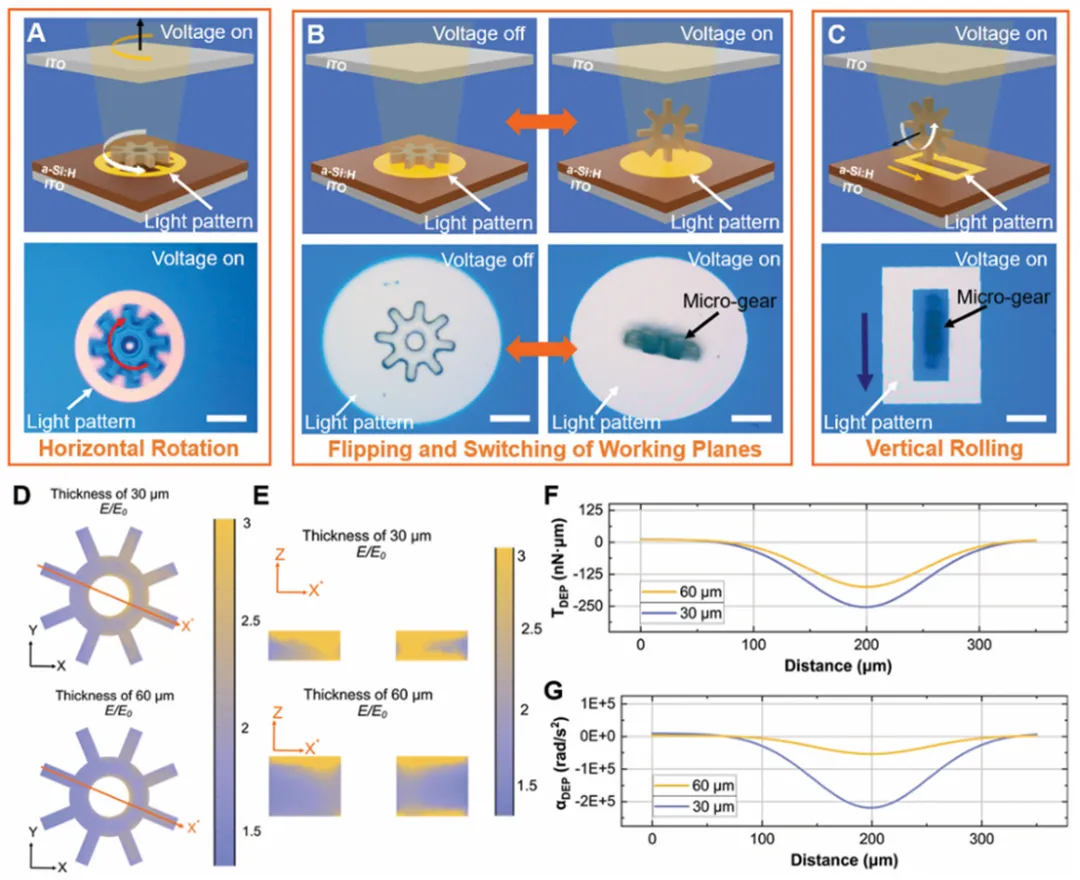

The team leveraged programmable light patterns to control OET, utilizing charge repulsion and dielectrophoretic levitation to achieve precise flipping, suspension, and 3D assembly of microgears. The 30μm-thick microgears used exhibit superior flip dynamics (angular velocity: 1.2 rad/s), enabling flexible switching of working planes. This breakthrough liberates micromachines from 2D constraints.

2: Microgear flipping behavior.

(A) Schematic and microscopy images of horizontal rotation.(B) Microgear lying flat when voltage is off (left); circular light pattern flips it upright.(C) Upright gear rolls vertically driven by a hollow rectangular light pattern.(D–E) Simulated relative electric field distributions of 30μm/60μm gears in XY/XZ planes.(F–G) Calculated dielectrophoretic torque and angular acceleration at different positions.

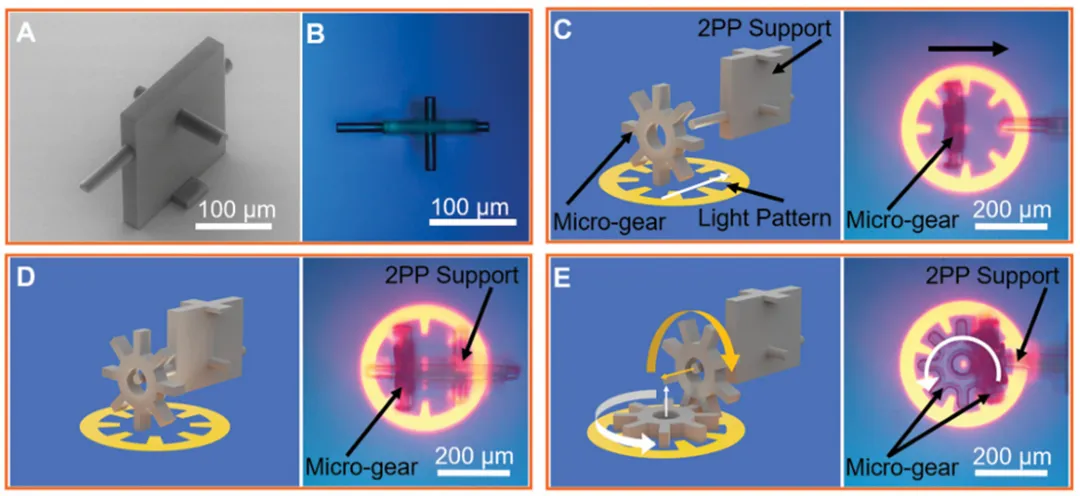

OET-based microgear assembly and actuation.

(A) SEM of 2PP-printed support. (B) Top-view microscopy of support.

(C) Assembly schematic/experimental images. (D) Interconnected structure.

(E) 3D cross-plane microgear set operation schematic/experimental images.

(Preceding Figure 4)

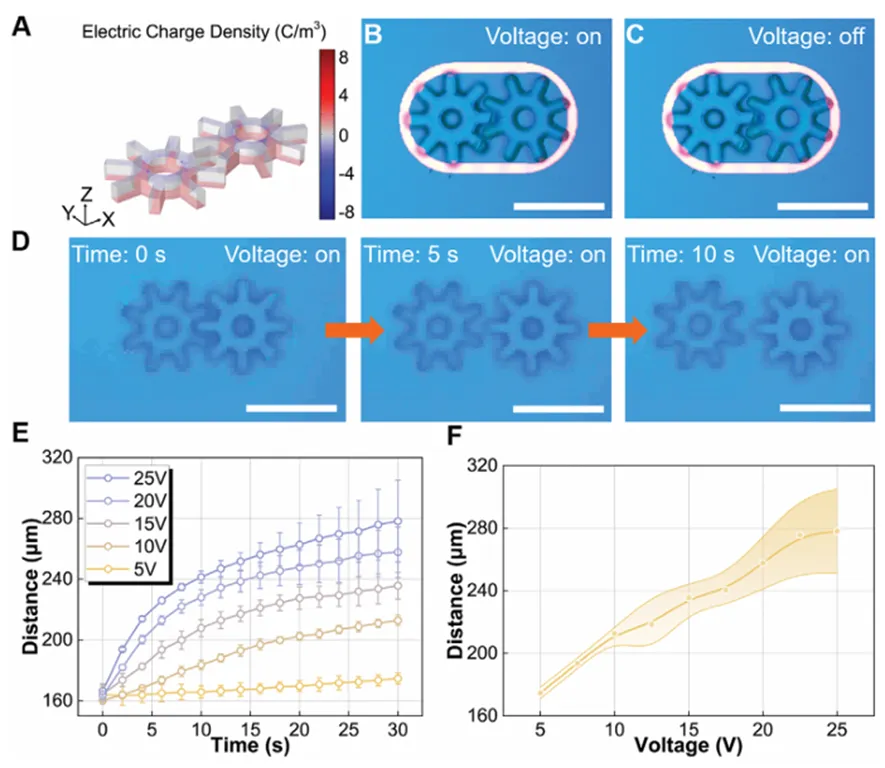

Surface charges on microgears generate up to 2,511.8 pN of repulsive force, effectively reducing inter-gear friction akin to lubrication in macro-mechanical systems. Dielectrophoretic levitation (~5.8μm above substrate) further minimizes friction. This "electronic lubrication + levitated bearing" mechanism offers new insights for micro-mechanical design.

Gear repulsion mechanism.

(A) Simulated surface charge distribution. (B) Light-induced gear meshing.(C) Voltage cut-off: minimal motion change. (D) Light cut-off: voltage-induced separation.(E) Gear spacing vs. time under varying voltages. (F) Measured final spacings.

Bio-Inspired Design from the Macro World

Inspired by macro-scale systems (e.g., automotive bevel gears), the team replicated mechanical transmission principles at microscale—demonstrating the applicability of macro-scale engineering in micro-domains for designing complex micromachines.

II.Summary and Outlook

(Preceding Impact List)

This breakthrough will profoundly impact:

- Biomedicine: 3D-operating micro-surgical robots for precision vascular interventions.

- Targeted Drug Delivery: Multi-component cooperative transport through biological barriers.

- MEMS: Novel 3D micro-sensors/actuators for microrobotics advancement.

Instrument Section

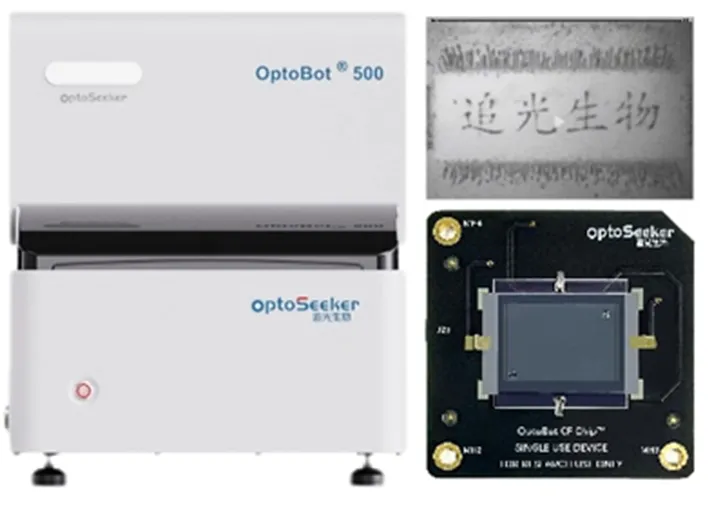

This study utilized the OptoBot®500 optoelectronic tweezer microfluidic platform (https://www.optoseeker.com/) developed by Shenzhen optoseeker. As China’s first commercial automated OET system, it offers technical reliability and ease of operation, and is deployed at top universities (Tsinghua, USTC, BIT, SUSTech).

Derived from Prof. Shuailong Zhang’s BIT research, OptoBot®500 enables sub-micron particle manipulation with applications including: nanomaterial assembly, microrobot (motor/gear) control, nanoscale mechanical characterization, OET-microfluidics integration, cell sorting/manipulation, and biomedical innovation. Related work has produced >50 high-impact papers (Nature/Science family journals, PNAS). Its domestic development provides crucial R&D infrastructure.

OptoBot®500 system and particle patterning

OptoBot®500 system and particle patterningAcknowledgements & Funding

The team acknowledges BIT’s Analytical Testing Center. Support was provided by: National Natural Science Foundation of China (Outstanding Youth/General Programs), National Key R&D Program, Beijing Natural Science Foundation (Key/General Programs), and Chongqing Natural Science Foundation (Outstanding Youth/General Programs).

Article Info (*Corresponding Authors)

Gong Li, Bingrui Xu, Xiaopu Wang, Jiangfan Yu, Yifan Zhang, Rongxin Fu, Fan Yang, Hongcheng Gu, Yuchen Huang, Yujie Chen, Yanfeng Zhang, Zhuoran Wang, Guozhen Shen, Yeliang Wang, Huikai Xie, Aaron R. Wheeler, Jiafang Li*, Shuailong Zhang*, “Crossing the Dimensional Divide with Optoelectronic Tweezers: Multicomponent Light-Driven Micromachines with Motion Transfer in Three Dimensions”, Advanced Materials, 2025, 37, 2417742.

Publication

https://advanced.onlinelibrary.wiley.com/doi/abs/10.1002/adma.202417742

Author Profiles

Gong Li: Ph.D. candidate at BIT’s School of Integrated Circuit and Electronics. Research: OET, light-driven micromechanical systems, OET algorithms. Published in Advanced Materials, Microsystems & Nanoengineering, Nano Letters, etc.

Shuailong Zhang: Professor/Ph.D. supervisor at BIT’s School of Integrated Circuit and Electronics (Prof. Huikai Xie's team); Chief Scientist of two 14th Five-Year National Key R&D Projects; 2019 National Young Talent; 2024 Chongqing Outstanding Youth Fund Awardee; Deputy Director, Engineering Research Center for Integrated Opto-Mechatronics Microsystems (MOE); Jiusan Society Deputy Chair at BIT. Research: Bio-nano manipulation, OET, microfluidics, biochip/sensors, microanalysis systems, scientific instrumentation.

Group: https://www.x-mol.com/groups/zhangshuailong

Jiafang Li: Distinguished Professor/Ph.D. supervisor at BIT’s School of Physics; NSFC Outstanding Youth Scholar; National Young Top-Notch Talent; core member of NSF’s "Extreme Light Field Manufacturing" project; Secretary, Party Committee of BIT’s School of Optoelectronics. Research: Light-matter interactions in plasmonic/photonic structures; nanokirigami, femtosecond laser 3D micro/nano fabrication.